Some Ideas on China Injection Molding You Should Know

Wiki Article

An Unbiased View of China Injection Molding

Table of ContentsSome Known Questions About China Injection Molding.The Facts About China Injection Molding UncoveredOur China Injection Molding PDFsWhat Does China Injection Molding Mean?Examine This Report about China Injection MoldingGetting My China Injection Molding To Work

Small Design Mistakes Have BIG Expenses with Shot Molding Ahead of time costs have a tendency to be very high as a result of design, testing, and also tooling demands. If you are going to generate parts in high quantities you desire to make certain you obtain the style right the very first time. That is much more complicated than you may think.

Await High Tooling Costs for Shot Molding Tooling is practically a project in and also of itself and also just one stage of the whole shot molding process. Prior to you can create an injection molded part you initially need to make and also prototype a component (probably using CNC or 3D printing).

Our China Injection Molding Diaries

And normally after substantial testing in both of the aforementioned phases, you get to injection mold and mildew a part. As you can envision, every one of the version called for to get the device proper previous to mass production needs both time as well as money. It is rare that you would model an injection molding device.This is very difficult and also in a lot of cases may mean requiring to junk the device (or part of the device) completely and also begin over. In other instances you could be able to weld steel right into the tooth cavity that is unwanted. Uniform Wall Thickness is Critical Injection molding demands uniform wall thickness.

Maintaining wall surfaces from being also thick is essential to stop variances in the cooling procedure leading to flaws like sink marks - China injection molding. A great policy of thumb is to maintain wall surfaces less than or equal to 4mm thick. The thicker the walls the a lot more material you will certainly utilize, the longer the cycle time will be as well as the higher your expense per part will certainly be.

Little Known Questions About China Injection Molding.

For an example of a huge injection built component, take into consideration the shopping carts at Target. Although the equipment exists to mold and mildew really huge items (e. g. 1000 bunch presses roughly find here the dimension of a train's cottage), utilizing it is very pricey. For this factor, items that are larger than a common injection molding equipment's ability are most typically created in numerous items.

Is Shot Forming the Right Choice for My Task? Before you endeavor to create a part by means of shot molding take into consideration a few of the following points.

Our China Injection Molding Diaries

From there, you'll intend to identify the variety of components produced at which you anticipate to recover cost on your investment (consider the prices of layout, testing, production, assembly, advertising and marketing, and also circulation along with the anticipated cost factor to buy). Integrate in a conventional margin. And do not forget entry costs.

i was reading this Make certain you recognize this critical point up front. Next off, Allow's Talk Style Factors to consider When it involves component layout, you want to design the component from the first day with injection molding in mind. Streamlining geometry and reducing the variety of components early on will certainly pay dividends in the future.

The 30-Second Trick For China Injection Molding

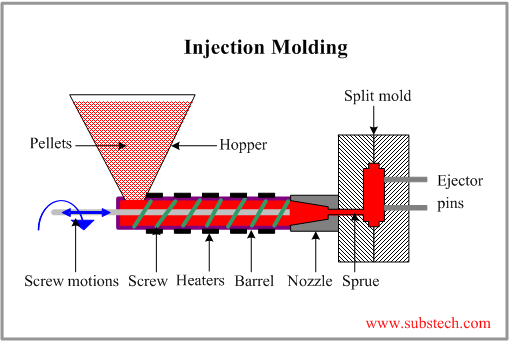

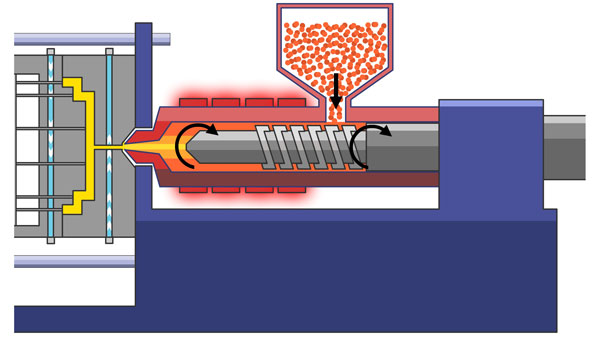

It is likewise useful for settled models that are utilized for customer and/or item screening. Prior to this late stage in production, nevertheless, 3D printing is a lot more budget friendly and flexible for items in the early stages of design.Components Injection molding is the most generally used manufacturing procedure for the fabrication of plastic components. A wide array of products are made utilizing injection molding, which differ substantially in their size, complexity, and also application. The shot molding procedure calls for making use of an injection molding machine, raw plastic material, and also a mold.

The steps in this process are explained in higher detail in the next area. Shot molding is utilized to generate thin-walled plastic components for a wide range Visit This Link of applications, among one of the most usual being plastic housings. Plastic real estate is a thin-walled unit, commonly needing several ribs as well as employers on the inside.

Indicators on China Injection Molding You Should Know

Process Cycle The procedure cycle for injection molding is really brief, commonly between 2 secs and also 2 minutes, and also contains the adhering to four stages: Securing - Before the injection of the product right into the mold and mildew, both halves of the mold and mildew should first be safely shut by the clamping unit.The hydraulically powered securing system presses the mold halves together and also exerts adequate pressure to maintain the mold and mildew securely closed while the product is infused. The time required to close and also clamp the mold and mildew is reliant upon the maker - bigger machines (those with higher securing pressures) will call for even more time.

Report this wiki page